Spike

Sustainable washing system with circular economy

By using Spike stones 98% of the sludge produced in pumice treatment is eliminated, leading to a reduction in filtering and disposal costs and the time required in enzyme treatment is reduced. Spike is fully recyclable and regenerable.

Spike has much longer durability. The lifespan of Spike stones, using industrial washing machines, is about 5,000 hours. After 3,000 hours of use, the weight and size of the stones are only reduced by about 6%. The average weight loss during 1 hour of washing in a normal 3500-litre stonewashing machine, using 80 kg of Spike stones, is only about 1.5 grammes.

What are the benefits?

1.

The low water level in the drum during the washing stage, together with the elimination of the double rinsing required to remove pumice residues in the fabric, saves around 1,500 litres of water for each wash.

2.

When Spike loses its efficacy, the material can be fully recycled and regenerated into new Spike stones.

3.

There’s no longer a need to excavate pumice and transport it from faraway countries. They reduce the transportation of sludge to landfills, thereby dramatically reducing CO₂ emissions caused by transportation vehicles.

4.

The product’s long lifespan eliminates warehouse storage costs for new pumice and residual sludge, with a consequent reduction in general costs (loading/unloading/cleaning).

5.

The Spike stones can be left inside the drum throughout all of the operations, from the desizing process right through to the final rinse.

6.

By using Spike stones, you will no longer have to remove pumice residues from between the yarns of the denim, thereby eliminating the greyness that’s typical of the stone-washing process. Spike stones will leave your garments soft and shiny, by reducing the “pilling” effect.

Technical characteristics

They comes in different sizes and can be used for a wide variety of textiles.

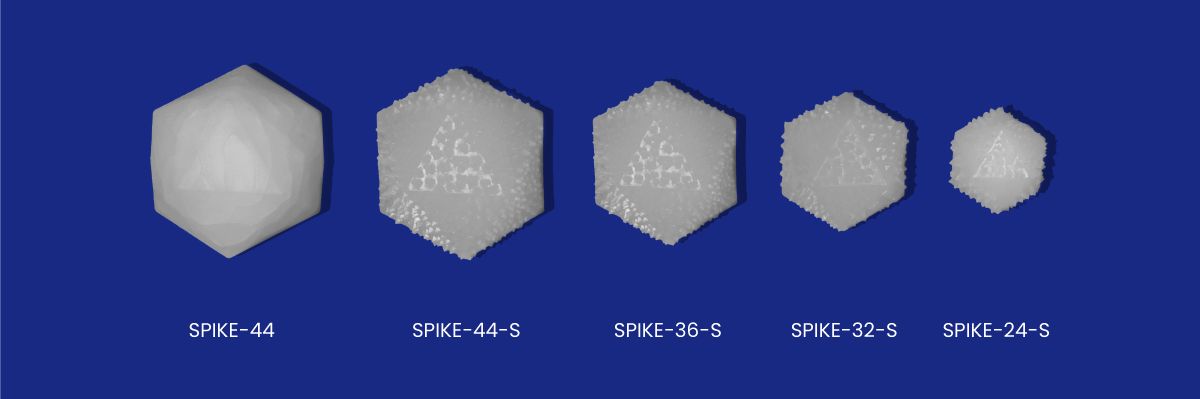

The Spike stones are icosahedral and come in 4 different formats: 44 mm smooth – 44 mm knobbly – 36 mm knobbly – 32 mm knobbly – 24 mm knobbly

The innovative composition of the material also makes it possible to create stone-wash effects on dyed, lightweight, stretchy and delicate fabrics, avoiding the risk of tearing that comes with the use of pumice stones.

Using Spike stones means you will no longer have to clean pumice stone sediment from the drains. They don’t cause damage to the washer drum, thereby increasing the life span of the washing machine and reducing maintenance costs.

They create less noise in the work environment as they turn in the drum.

Strengths

Eliminates sludge

Reduces the amount of water used during washing and rinsing

Long lifespan

Recyclable product

Reduces co₂ emissions

Doesn’t dirty the machines or cause damage, making it possible to use them for other processes

Doesn’t leave residue between the yarns of the fabrics; leaves them soft and shiny

Different formats for different needs

No more warehouse storage and elimination of unloading/loading times for pumice/sludge

How to use

The optimal weight ratio is 1 part fabric to 1.5/2 parts Spike (50 kg fabric = 80/100 Kg Spike stones). For the best results, use machines with a capacity of over 2,500 litres.

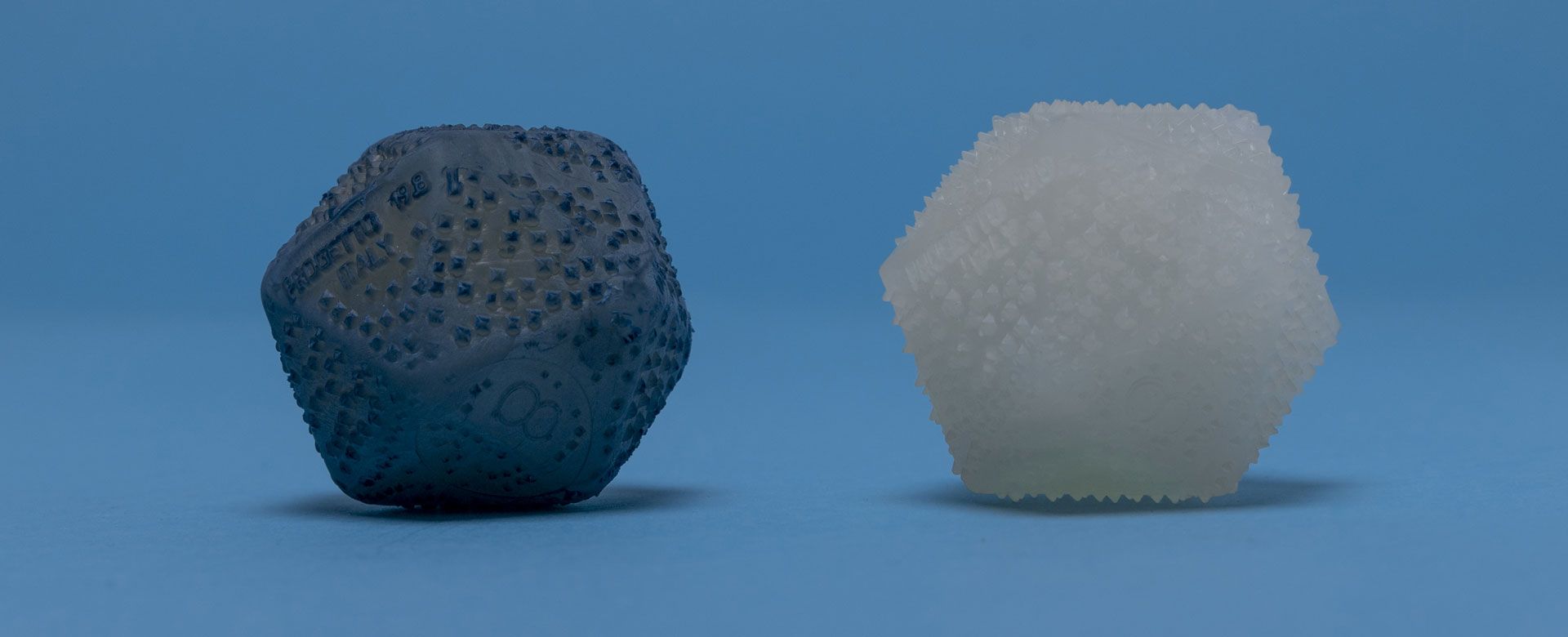

Spike stones should be used in addition to enzymes. When used together, the time of the stonewashing process is reduced by 20%. The knobbly surface remains intact for about 2,000 hours, although once consumed the stones will continue to “rub” the fabric.

Comparison of used Spike 1800 hours and new Spike

Do not use Spike stones with: potassium permanganate – hydrogen peroxide permanganate > 40° or other oxidants that may weaken the material’s molecular structure